Lil bit of history.

Harald and I were planning to develop and release a rather large subject in plastic.

We were thinking that this large object is a great idea. Doing something like that in plastic is possible and it shoud be a lot of fun. Its not about the money. We all are busy. Its because its

friggin cool.

So, I did some brief estimates on what kinda processes we will need to master and how complex the whole thing is going to be. I was like "no way we will be able to pull that off from zero. That

would just slow down and disappear." It was too huge for a debut.

It was one of those rainy days in January in Northern Germany and I stood outside and had a cigarette. I was watching the grey skies, puffin some smoke innit and I thought, "Thats really too

difficult and too complex for a first, man. Also we only have insufficient reference data. Thats not goinna to materialize. We will lose momentum and its goinna beach."

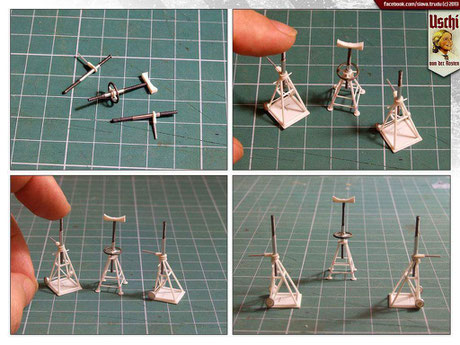

Pretty much at the same time I saw Marco Leibisch playing on facebook with some scratch built Luftwaffe jacks as part of a 229 project he just finished. These were the same which Slava Trudu

scratch-built for his epic REIMAHG diorama back in 2013. I was like "HEUREKA! Thats a great thing for a start! Its easy, we

have references, invest is not too high and it should be successful once it is released." IDEAL!

So, I contacted Marco and he agreed to share what he found out so far. So actually he helped me to visualize the product for the first time and that was what kinda triggered the idea. Marco

provided support from this point to the very present day. Thank you, Marco!

Slava Trudu´s 72nd scale German Jack Stands

Marco´s scratch built jacks

All right. Now, how are we getting to the next level?

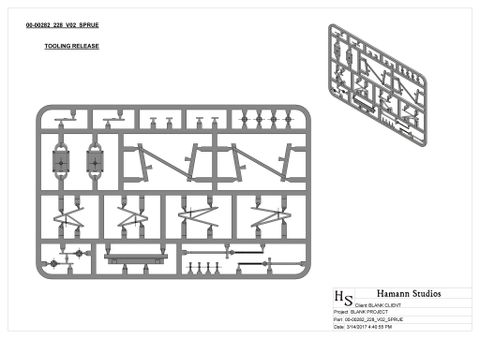

Right. We need some CADs As far as CAD is concerned, there was just one name in my mind actually. Pete Hamann. For me he was my favored person I wanted to work with. I know Pete

now for a couple of years and I saw his CADs every now and then. He used to work for a major aircraft manufacturer and he has a very professional working-style. It´s always very inspiring to talk

to him. He has that cool and calm kinda attitude, you know? The one that allows think-tank athmosphere and creativity while you talk. That stuff.

So, I asked Pete if he would be in and... HE SAID YES!

Having Pete onboard was an important milestone on the way to a (once maybe) finished kit.

Pete Hamann at work. MAGIC CAD skillz!

Now, who can we talk to when it comes to production? It takes professionalism, trust, good communication, mutual understanding and you dont wanna see your s**t being hijacked, you know?

Hm....

Thats were Harald came into play again. MBK and TAKOM has an excellent relationship and both sides have a great interest to keep it that way. Also, TAKOM is able to produce the quality we were

after. We asked for a quote based on Pete´s files and it sounded good so... BINGO! We have just found a manufacturer!

From this point everything went pretty smooth. We had some slow downs because of the Nuremberg Toy Fair and the Chinese New Year but we managed to pick up and keep momentum again.

That day the prototypes arrived was just awesome. That was magic. Harald brought it from Shizuoka where he met with TAKOM. Awesome. Its really cool when you have that thingy in your hands for the

first time.

The test builds went great, just one minor fix was neccesary. We have put our order in and....wow....WE MADE IT.

The whole process took about 6 month. Given that this was the first time and we lost like 6-8 weeks because of external circumstances...actually not too bad.

WE all hope that you are satisfied and we do look forward to see you playing with the product.

JACK IT UP my friend! HIER AUFBOCKEN! ;-)

CREDITS

Original Idea: Alexander Glass / Marco Leibisch

Business Angel: Harald Bauske (MBK Distribution)

Product Management: Alexander Glass

CAD: Pete Hamann

Tooling / Production Management: TAKOM

Lead Packaging Designer: Alexander Glass

Assist Packaging Designer: Harald Bauske

Manual Design: Pete Hamann

Test builds: Alexander Glass, Pete Hamann, Christian Schiller, Marco Leibisch

Marketing and Sales: Alexander Glass

Special thanks to: Alexander Nevsorov, Jim Hatch and Bill Eady for further research and support. Also special thanks to the all people in the DAS WERK PUBLIC group on facebook for the encouragement and support.